Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Urban centralized heating systems are composed of four main components: heat sources, heating networks, heat exchange stations, and various types of heat consumers. These systems provide efficient heat supply through centralized heat sources, using hot water or steam as the transmission medium to meet the thermal demands of an area or an entire city, primarily for industrial use and residential heating.

By employing a combination of sensors with specific functions, heating companies can conveniently monitor the heat exchange stations across different districts and the indoor temperatures of residents in real-time. Coupled with remote control systems that adjust the supply and return water, this setup achieves efficient heating, thereby preventing excessive energy waste and increased carbon emissions.

In the process of urban centralized heating, three types of sensors are commonly used:

Flow Meters

Temperature Sensors

Pressure Sensors

Applications in Heat Exchange Stations:

Flow Meters: In heating systems, flow meters monitor the velocity and volume of heating water, assisting heating companies in understanding the overall output of heating water and managing the difference between the outflow and inflow volumes, ensuring proper water replenishment and heating effectiveness.

Temperature Sensors: Within heat exchange stations, temperature sensors are used to monitor both the outgoing heating water temperature and the indoor temperatures of residents. Real-time temperature feedback helps in adjusting the supply water temperature and detecting equipment failures promptly.

Pressure Sensors: Heating systems typically require a certain pressure (around 1.0-1.5 bar) to function properly. Pressure sensors are instruments designed to monitor the liquid pressure within the heating system.

Case Study

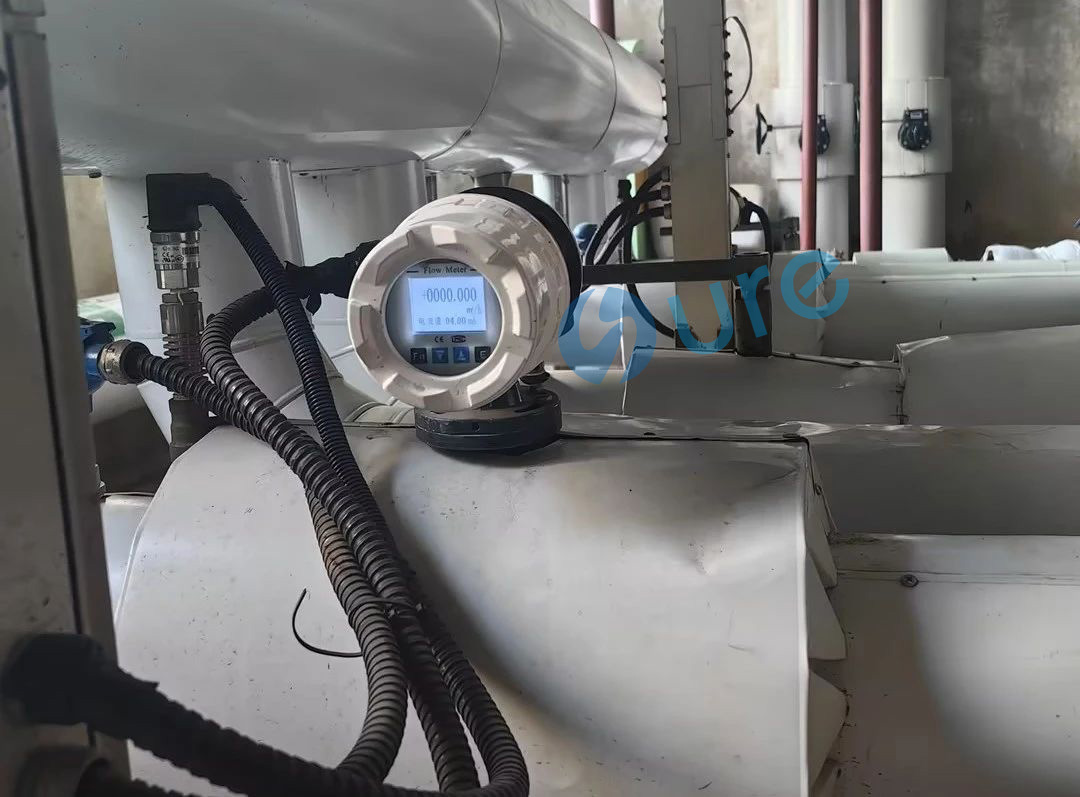

A project involved the construction of three new heat exchange stations in a residential area to ensure winter heating for older communities. Each station required three flow meters for measuring the flow in the primary and secondary water supply networks. The instruments needed to withstand high temperatures to cope with high network temperatures. Additionally, negative pressure situations often occur in the water supply network during maintenance or emergencies, so the flow meters installed on the water supply network must have excellent negative pressure resistance. Furthermore, the heat exchange stations required four temperature sensors and four pressure sensors with display capabilities for controlling primary supply and return water temperatures, secondary supply water temperature, and secondary supply and return water pressures.

Solution

Based on the actual site conditions, Sure Instrument team developed a targeted solution for the client, matching the appropriate flow meters, temperature sensors, and pressure sensors according to the client's site specifications, temperature, and flow range to ensure measurement accuracy and stability. For flow meters, electromagnetic flow meters were chosen because the primary network is designed for supply water at 130°C/return water at 70°C, using F46 lining, and the secondary network is generally designed for supply water at 80°C/return water at 60°C, using Teflon lining. The circulating water composition is simple and non-corrosive, so 316L electrodes were selected.

Considering that heating is typically only conducted in winter and heat exchange stations may not have good sealing measures, leading to condensation from the meeting of indoor and outdoor temperature differences, an IP68 protection rating was chosen. Suitable temperature and pressure sensors were also configured.

Customer Feedback

The heat exchange station equipment is being commissioned in preparation for this winter's heating. The product performance is stable, ensuring the accuracy of data collection at the heat exchange stations. Sure Instrument's staff cooperated in the installation guidance and arranged for technical personnel to train the heat exchange station staff on instrument operation and maintenance. Field instrument personnel have expressed that Sure Instrument's service is excellent, and the product platform's consistency facilitates maintenance, improving work efficiency. Additionally, the instruments are equipped with self-diagnostic functions, ensuring the safety of use.

Product Recommendation

Electromagnetic Flow Meter:

Capable of measuring conductive liquids, especially suitable for media such as sewage, chemical solutions, and tap water.

Accuracy: Class 0.5 and Class 0.2.

Low flow velocity measurement, capable of measuring flow velocities as low as 0.1 m/s.

Meter body sizes range from DN4 to DN2000.

Equipped with explosion-proof capabilities, with protection ratings of IP65 and IP68.

Features multiple communication options, including RS485, HART, 4G, and NB-IoT.

Temperature Transmitter:

Equipped with linearization correction functionality to ensure accurate measurements .

Thermocouple temperature transmitters feature automatic cold junction compensation to account for voltage variations at the cold junction .

Spring-loaded temperature sensing elements offer excellent seismic resistance and robust performance under vibration .

Wide measurement range coupled with high measurement accuracy .

High mechanical strength and excellent pressure resistance capabilities .

Short response time, ensuring swift reactions to changes in the measurement environment .

Pressure Transmitter:

Easy installation, suitable for direct mounting or mounting with a support bracket.

High precision, high stability, and high reliability, with strong resistance to frequency variation interference.

Capable of measuring gauge pressure, absolute pressure, and negative pressure.

Zero point is relocatable and the measurement range is adjustable.

Supports networking applications.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.