Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

The textile dyeing and printing industry faces significant challenges in energy and resource management, with high costs tied to water, steam, electricity, and chemicals. To address these challenges, precise flow measurement solutions are critical for optimizing processes, reducing waste, and lowering operational costs. Here’s how electromagnetic flow meters and vortex flow meters are driving sustainable improvements in a real-world dyeing facility.

Textile dyeing involves three energy-intensive stages:

Pre-treatment (Desizing): Removes impurities using chemicals and hot water, consuming vast amounts of water, steam, and electricity.

Dyeing: Requires precise dosing of dyes, alkalis, and additives at high temperatures, generating heavy wastewater loads.

Post-treatment (Drying/Finishing): Relies on steam-powered drying and heat-setting, contributing to high steam consumption.

With complex workflows and strict environmental regulations, inefficient resource tracking can lead to skyrocketing costs and compliance risks.

Case Study: Smart Flow Metering Solutions

A leading dyeing manufacturer partnered with Sure Instrument to implement tailored flow measurement systems across its facility.

Key Requirements:

Accurately measure steam consumption for cost allocation across 15 high-temperature dyeing machines.

Track alkali solutions, cooling water, and freshwater usage in corrosive environments.

Monitor wastewater volumes sent to treatment plants for internal cost-sharing.

Solutions Deployed:

LDG-Electromagnetic Flow Meters

Application: Measurement of alkaline solutions, cooling water, and freshwater.

Why It Worked: Superior corrosion resistance to harsh chemicals (e.g., caustic soda) ensured longevity and reliability.

Impact: Enabled precise chemical dosing, reduced wastewater overuse, and supported water balance testing for compliance.

Check the detail: Electromagnetic Flow Meter Manufacturer, Seawater Flow Meter

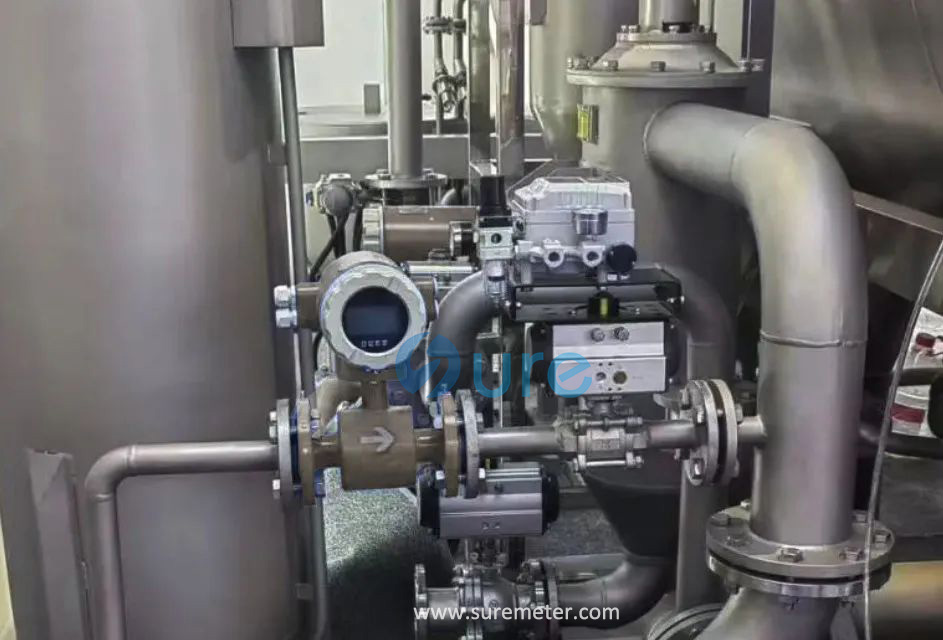

LUGB-Vortex Flow Meters

Application: Steam flow measurement in drying machines and main steam pipelines.

Why It Worked: High-temperature tolerance (up to 420°C) and stability in high-pressure environments.

Impact: Accurate steam tracking allowed per-department cost allocation and identified energy-saving opportunities.

Check the detail: Oem Air Flow Meter Manufacturer, Steam Vortex Flow Meter | Sure

Results & Benefits

Cost Reduction: Real-time data on steam, water, and chemicals helped slash resource waste by 15–20%.

Compliance: Wastewater volume tracking simplified environmental reporting and treatment cost sharing.

Sustainability: Improved process control reduced overall carbon footprint and supported circular water reuse initiatives.

Why Choose Sure Instrument?

Our expertise in flow measurement ensures tailored solutions for textile dyeing’s unique demands:

✅ Corrosion-resistant designs for aggressive chemicals.

✅ High-temperature/pressure compatibility for steam systems.

✅ Integrated data analytics to drive energy efficiency.

Join the growing number of textile manufacturers leveraging smart metering to cut costs and meet sustainability goals.

Contact us today to learn how Sure Instrument’s flow meters can transform your dyeing processes!

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.