Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

A Coriolis meter works on the Coriolis Effect, hence it is named so. Coriolis meters are considered to be true mass meters since they tend to measure the mass rate of flow directly while other flow meter technologies measure volumetric flow.

Since mass does not change, no adjustments are needed for varying fluid characteristics. Hence, a Coriolis meter operates in a linear fashion.

These types of meters exist in a variety of designs.

The most common type of unit includes

a U-shaped flow tube

a sensor assembly

an electronics unit

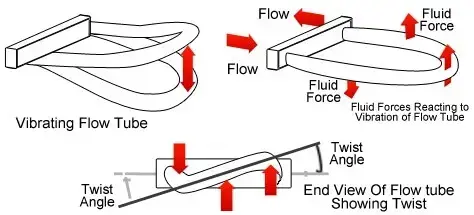

In this meter unit, the liquid passes through a U-shaped tube which vibrates in an angular harmonic oscillation. Coriolis forces will then deform the tube and a further vibration component gets added to the already oscillating tube. This added vibration element results in a phase shift or twist in a few parts of the tubes.

This resulting phase shift which is directly proportional to the liquid mass flow rate is measured with the help of sensors. This measured information is further transferred to the electronics unit where it gets transformed to a voltage proportional to mass flow rate. A Coriolis meter is shown in the figure below:

The flow is guided into the U-shaped tube. When an oscillating excitation force is applied to the tube causing it to vibrate, the fluid flowing through the tube will induce a rotation or twist to the tube because of the Coriolis acceleration acting in opposite directions on either side of the applied force.

For example, when the tube is moving upward during the first half of a cycle, the fluid flowing into the meter resists being forced up by pushing down on the tube. On the opposite side, the liquid flowing out of the meter resists having its vertical motion decreased by pushing up on the tube.

This action causes the tube to twist. When the tube is moving downward during the second half of the vibration cycle, it twists in the opposite direction.

This twist results in a phase difference (time lag) between the inlet side and the outlet side and this phase difference is directly affected by the mass passing through the tube.

An advantage of Coriolis flow meters is that it measures the mass flow rate directly which eliminates the need to compensate for changing temperature, viscosity, and pressure conditions.

Advantages:

U shape design-provides excellent stability and repeatability

Dedicated ASIC with digital closed-loop control(DLC) improves the performance of gas-liquid flow measurement

Dynamic vibration balance(DVB) technology enhances system stability

2-point temp. compensation and process pressure compensation

Special configurations for diffcult applications (e.g. high temp.)

SURE of Variable Area Flow Meters

| Measuring Tube | SS316L; Hastelloy C |

| Accuracy | ±0.1%; ±0.2%; ±0.5%; |

| Output | 4-20mA; Pulse |

| Comm. | RS485; HART |

| Explosion Proof | ExdibIICT6Gb |

| Protection | IP67 |

| Density Measurement Accuracy | Error: 0.0005g/cm³ (0.5g/m³ ) |

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.