Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

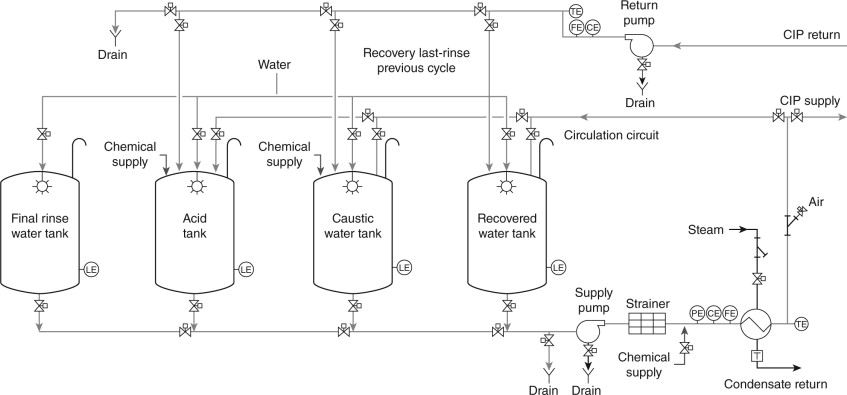

Since the 1980s, the cleaning of equipment has increasingly been automated, particularly in the dairy, beverage, and other industries that utilize continuous pipeline operations. Many dairy plants have adopted the practice of automatic cleaning in place, where the water and cleaning solutions used for rinsing circulate within the equipment's pipelines and production lines in a closed loop, eliminating the need for disassembly. This technique is known as Clean-In-Place (CIP), also referred to as in situ or localized cleaning.

CIP is extensively applied across highly mechanized food and beverage manufacturing sectors, including pharmaceuticals, beverages, dairy, fruit juices, purees, jams, and alcoholic products. In-place cleaning eliminates the need to dismantle or relocate equipment. Instead, it leverages detergents and washing water to flush the interior surfaces of the equipment at high velocities, creating a mechanical action that dislodges and removes dirt. This method is effective for cleaning components such as pipelines, pumps, heat exchangers, separators, and valves, and is well-suited for the stringent hygiene requirements of production equipment cleaning and purification processes.

How does CIP work?

The CIP process typically involves three stages: pre-rinse, cleaning, and post-rinse. Each stage is meticulously planned and executed to remove organic deposits, kill microorganisms, and leave the surfaces ready for the next production cycle.

1. Pre-rinse: The initial rinse removes loose particles, preparing the surface for the cleaning solution.

2. Cleaning: A concentrated alkaline or acid solution is circulated to break down and remove organic matter and sanitize surfaces.

3. Post-rinse: A final rinse with clean water flushes away the cleaning solution and any remaining residue.

Why do we need flow meters in CIP systems?

Accuracy: Flow meters ensure that the precise amount of cleaning solution is used, optimizing the cleaning process.

Hygiene: Contactless and non-intrusive flow meters reduce the risk of contamination.

Reliability: Flow meters provide consistent readings, reducing the likelihood of human error.

Automation: Integrated with control systems, flow meters automate the CIP process, improving efficiency.

Maintenance: Many flow meters used in CIP systems require minimal maintenance, reducing downtime.

The integration of various flow meters in the CIP system is not just about ensuring hygienic standards; it's also about understanding the intricate mechanisms that drive these devices. Let's delve deeper into the working principles of the flow meters mentioned earlier and understand how they contribute to the efficiency and accuracy of the CIP process.

Electromagnetic Flow Meter

Electromagnetic flow meters operate based on Faraday's law of electromagnetic induction. They apply a magnetic field perpendicular to the flow direction, inducing a voltage in the conductive liquid that is proportional to the flow velocity. This principle allows for contactless measurement, eliminating the risk of clogging and providing a highly accurate flow rate.

Liquid Turbine Flow Meter

As liquid flows through the turbine meter, it causes the rotor to spin. The rotation speed of the rotor is directly proportional to the flow rate. This analog measurement is then converted into a digital signal for precise control within the CIP system.

Ultrasonic Level Meter

Ultrasonic level meters work on the principle of echo ranging. A transducer sends out an ultrasonic wave that reflects off the surface of the liquid and returns to the transducer. The time taken for the wave to travel to the surface and back is used to calculate the level of the liquid.

Conductivity Meter

The meter works by passing a small, known electrical current through the solution via two electrodes. The solution's ions move in response to the electric field, creating a flow of charge that is measured as electrical conductivity. Since conductivity is affected by temperature, the SCD/SS includes a temperature sensor to measure and adjust for the temperature of the solution, ensuring accurate salinity readings across a range of temperatures. By understanding the solution's conductivity and salinity, users can make informed decisions about water quality, process control, and product consistency.

Although not flow meters, temperature and pressure transmitters are integral to the CIP system.

Temperature and Pressure Transmitters

Temperature transmitters measure the heat energy of the fluid, while pressure transmitters measure the force per unit area exerted by the fluid. These measurements are critical for adjusting the CIP process parameters for optimal cleaning.

The CIP system is a sophisticated process that benefits significantly from the integration of various flow meters. These devices not only ensure the effectiveness of the cleaning process but also contribute to the overall productivity and safety of the food and beverage industry. As technology advances, the role of flow meters in CIP systems continues to evolve, providing even greater accuracy and efficiency in the pursuit of excellence in food production.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.