Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

The annealing process in the steel industry is a critical heat treatment step aimed at enhancing the internal structure and performance of metal materials. It involves heating metal to a specific temperature, maintaining it for a while, and then cooling it slowly. This process is designed to achieve a balanced state within the metal, resulting in improved mechanical properties and readiness for further heat treatments such as quenching and tempering.

The Role of Annealing in Steel Production

Annealing serves multiple purposes, including improving or eliminating organizational defects and residual stresses resulting from casting, forging, rolling, and welding. It prevents workpiece deformation or cracking, softens the workpiece for machining, refines grain to enhance mechanical properties, and prepares the material for final heat treatment.

Safe and Effective Use of Gas or Natural Gas

Heating media in steel production annealing lines typically involve gas or natural gas, which carry explosion risks. Ensuring the safe and effective use of these energy media involves a precise mixture of N2 and H2 in the annealing furnace. The special steel continuous annealing furnace requires decarburization (partial or complete) for both intermediate and final annealing, with finished steel demanding carbon content of ≤27ppm, with lower being better.

Decarburization and Protection Gas Control

Decarburization primarily relies on protective gases enhanced with humidity (H2O), which reacts with carbon in iron to form CO and H2. However, water can also cause oxidation in the steel plate, which is undesirable. Therefore, the humidity function must be controlled to both decarburize and prevent oxidation. This requires strict control over the ratios of hydrogen and nitrogen, the amount of water vapor, the directed flow of protective gases in the furnace, and the distribution of furnace pressure.

Application Case Study

A steelmaking enterprise uses a mixture of H2 and N2 as a protective atmosphere gas in their special steel continuous annealing furnace. The process requires a hydrogen concentration of 20%. To maintain a positive furnace pressure and prevent air intrusion, a certain amount of N2 is circulated and injected for cooling. When the pipeline reaches a certain temperature, H2 is added for insulation, demanding stable flow.The customer's pipelines are DN25 in diameter, with a working pressure of 50kPa.

Their requirements included

1. Precise measurement of the ratios of hydrogen and nitrogen.

2. Stable performance of the flowmeter.

3. Ensure production safety.

Solution and Customer Feedback

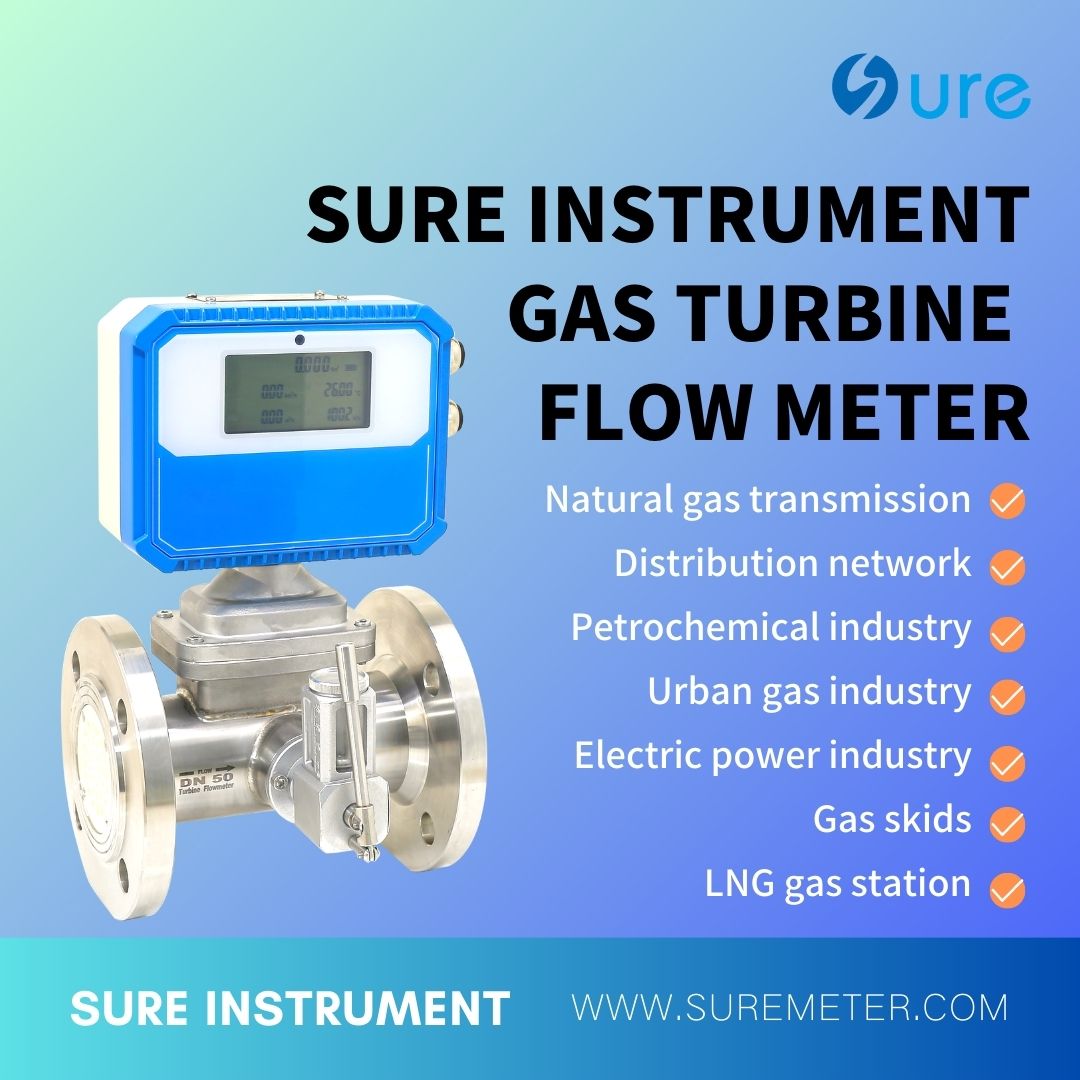

We provided the LWQ series gas turbine flowmeter with 1.5% accuracy for nitrogen measurement, chosen for its vertical installation without the need for oil filling. For hydrogen measurement, the thermal gas mass flowmeter was used.

The customer reported that since June 2023, all flowmeters have been operating stably, offering accurate and reliable measurement results. The precise control of gas flow in the special steel high-temperature annealing process is crucial, and our flowmeters have provided stable and reliable data support for the process, ensuring consistent improvements in production efficiency and product quality.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.