Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

In the pulsating heart of industrial operations, air compressors play a crucial role, providing the compressed air that drives a multitude of processes. The accurate measurement and control of compressed air are paramount for ensuring efficiency, reliability, and safety within these processes. Advanced flow metering solutions have become indispensable in achieving these goals, offering precise, real-time data that can optimize the performance of air compressor systems.

·Pressure Transmitters: Pressure transmitters are the sentinels of air compression systems, monitoring and ensuring that the system operates within safe and efficient pressure limits. They detect the working pressure, providing vital data for flow pressure compensation. Typically, these systems are designed to handle pressures ranging from 0.6 to 1.6 MPa, adapting to various industrial demands.

·Thermistors and Temperature Transmitters: Temperature is a critical parameter in air compression, affecting both the energy consumption and the output quality of compressed air. Thermistors and other temperature transmitters step in to measure the necessary temperature compensation for flow. They are calibrated to operate effectively within the ambient temperature range, typically up to 60°C, ensuring that the system performs within optimal thermal conditions.

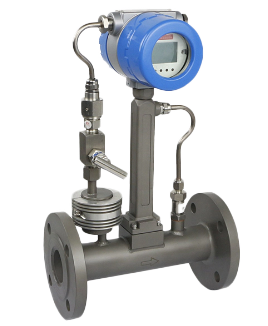

·Vortex Flowmeters: When it comes to measuring the rate of gas flow, vortex flowmeters stand out for their ability to generate precise, repeatable measurements. They operate on the principle of creating vortices in the fluid flow, which are then detected and used to calculate the flow rate. These flowmeters are particularly effective at temperatures around 60°C and pressures from 0.6 to 0.8 MPa, providing a reliable method for gas usage monitoring in pipes ranging from DN40 to DN150.

·Thermal Mass Flowmeters: Thermal mass flowmeters offer a high level of accuracy for measuring the mass flow of gases. They work by heating a sensing element and measuring the amount of heat required to maintain a constant temperature difference. This method is independent of the gas's compressibility, making it an excellent choice for applications where traditional methods may fall short.

Flow meters in air compression systems serve multiple purposes:

1.Efficiency Monitoring: By providing real-time data on the flow rate, flow meters help in identifying inefficiencies and areas for improvement.

2.Pressure and Temperature Compensation: They ensure that the system operates within the desired parameters, compensating for variations in pressure and temperature that could affect performance.

3.Energy Management: Accurate flow measurement is essential for effective energy management, helping to reduce unnecessary energy consumption and associated costs.

4.Process Control: Flow meters contribute to the overall process control strategy, enabling operators to make informed decisions and maintain process integrity.

5.Maintenance and Diagnostics: Advanced flow meters can predict maintenance needs and diagnose potential issues before they become critical, leading to fewer system disruptions.

The integration of advanced flow metering solutions into industrial air compression applications is a testament to the pursuit of operational excellence. These technologies not only enhance the performance and reliability of air compressor systems but also contribute to energy conservation and sustainable industrial practices. As industry continues to evolve, the role of flow meters will remain central to the optimization and advancement of air compression technologies.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.