Contact Us Right Away

If you run into any issue or have any question.

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

When it comes to fluid measurement, two "stars" stand out in the field: Turbine Flow Meters and Vortex Flow Meters. Both are adept at measuring flow rates, but they each have their unique strengths and applications. Let's dive into the specifics of their design principles, application areas, structural features, and measurement accuracy to understand their differences.

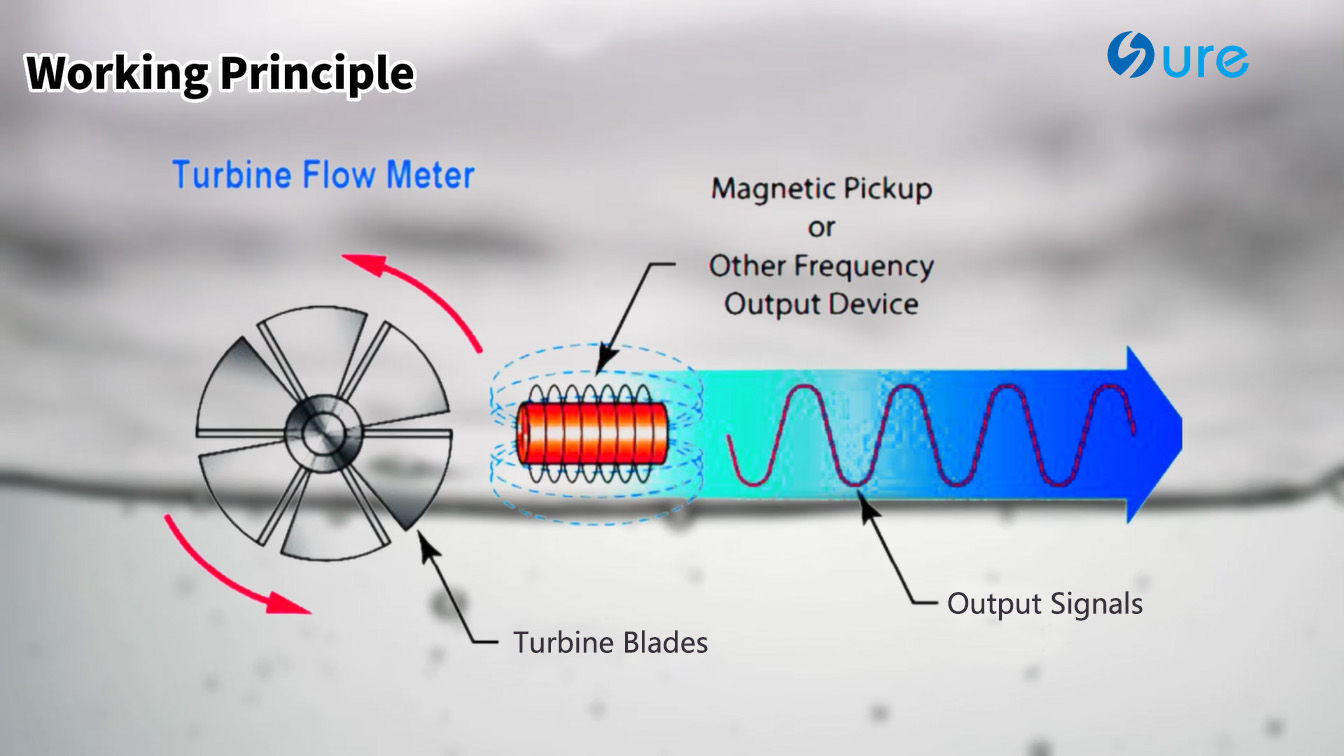

Working Principles

Turbine Flow Meters operate on the principle of a turbine rotating within a fluid. As the fluid passes through the pipe, it impacts the turbine blades, creating a driving torque that causes the turbine to spin. The rotational speed of the turbine is directly proportional to the fluid velocity within a certain range. By detecting the turbine's RPM, we can calculate the fluid's flow rate. Essentially, it harnesses the fluid's momentum to spin the turbine blades, measuring flow in the process.

Vortex Flow Meters, on the other hand, are designed based on the Karman vortex street principle. As the fluid flows past the vortex transmitter in the pipe, it alternately sheds vortices behind a triangular bluff body in proportion to the flow rate. The frequency of these vortices is related to the average velocity of the fluid passing the transmitter and its characteristics. By measuring the frequency of these vortices, we can determine the fluid's flow rate.

Application Areas

Turbine Flow Meters are widely used in industries such as oil, organic liquids, inorganic liquids, liquefied gas, natural gas, coal gas, and low-temperature fluids. They are known for their simple structure, few moving parts, lightweight design, ease of maintenance, and high flow capacity, making them suitable for high-parameter environments like high temperatures, pressures, and low temperatures.

Vortex Flow Meters are primarily used for measuring the flow rate of various media in industrial pipelines, including gases, liquids, and steam. They are characterized by low pressure loss, a wide range of measurement, high accuracy, and minimal influence from fluid properties such as density, pressure, temperature, and viscosity.

Structural Features

Turbine Flow Meters consist of a turbine, guide vane, casing, and transmitter. The turbine is supported at both ends by bearings and usually incorporates a preamplifier and a display device. Their simple design houses precision-machined blades and reduction gears that ensure high measurement accuracy.

Vortex Flow Meters include a triangular prism-shaped vortex generator and a flow transmitter. The flow channel is centrally set with a vortex street, and the cross-section is annular with a narrow opening in the middle. This design allows for more accurate measurement of fluid flow.

Measurement Accuracy

Turbine Flow Meters generally offer higher measurement accuracy, with an error range typically between ±0.5% and ±1%. However, they have certain requirements for fluid properties and must consider changes in viscosity, temperature, and pressure.

Vortex Flow Meters, while slightly less accurate than turbine meters, can still achieve an error range of ±1% to ±2%. They have lower requirements for fluid properties and a broader range of applications, making them suitable for fluids with impurities, dust, and particulates.

Suitable Media for Each Flow Meter

For Turbine Flow Meters:

High viscosity fluids: Turbine meters can measure a wide range of viscosities, from 0.5 to 20000 mPa·s, making them suitable for high viscosity fluids.

Fluids with extreme temperature or pressure changes: Turbine meters can measure media with temperatures up to +750℃ or pressures up to +42MPa, maintaining accuracy under extreme conditions.

High-precision flow measurement needs: Turbine meters offer a large range and accuracy up to ±1%, making them ideal for critical process control in industries like petrochemicals, metallurgy, and power.

For Vortex Flow Meters:

Liquids with suspended particles: Vortex meters are more tolerant of suspended particles, which can damage the delicate blades of turbine meters.

Liquids with gas or bubbles: Bubbles can affect the rotation speed of the turbine, making it difficult for turbine meters to measure accurately.

High-concentration corrosive solutions: Vortex meters can be made with corrosion-resistant materials to handle these media.

In conclusion, the choice between a turbine and vortex flow meter should be based on the characteristics of the medium and the measurement requirements. Understanding these differences will help you make an informed decision for your next flow measurement project.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.