Contact Us Right Away

If you run into any issue or have any question.

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

In the realm of industrial automation, the correct use of terms like "converter" and "transmitter" is crucial due to their specific meanings and applications. Let's clarify the proper use of these two terms and understand their roles in various scenarios.

Converter: Bridging the Gap Between Signals

Definition: A converter is a device that transforms one type of signal into another. This can include electrical signals or other forms such as optical or acoustic signals. In industrial automation, converters are primarily used for interfacing between different systems or devices to achieve signal compatibility and transmission.

Features:

Diverse Signal Conversion: Converters handle a variety of signal types, from analog to digital conversions, to different electrical signal transitions (e.g., serial port to RS485, USB to VGA, etc.).

Wide Application: They are extensively used for connecting and interfacing between various systems, such as Ethernet, RS485, MODBUS, and other communication protocols.

High-Quality Requirements: The conversion process demands that information remains undistorted, without delay or loss, placing certain demands on the linearity, input/output impedance matching, and isolation of the converter.

Transmitter: Standardizing Signal Output

Definition: A transmitter is a device that converts non-standard electrical signals or physical quantities into standard electrical signals (such as 4-20mA, 0-10V, etc.). These standard signals can be easily integrated into display instruments, control systems, or computers for display, recording, and control purposes.

Features:

Primary Use: Transmitters are mainly used to convert physical quantities like temperature, pressure, flow, and weak non-standard electrical signals into standard electrical signals.

High Stability and Accuracy: The converted signals meet the demands of industrial automation and process control.

Additional Functions: Transmitters often include signal amplification, linearization processing, and other functions to ensure signal accuracy and reliability.

Correct Usage Based on Function

When interfacing across systems or devices and the conversion involves signal types or interfaces, a "converter" is typically used.

When converting physical quantities or non-standard electrical signals into standard signals for further processing, a "transmitter" is the appropriate choice.

Application Scenarios

Converters are widely applied in industrial automation and communication fields for interface conversion.

Transmitters are mainly used in industrial automation and process control for the conversion of physical quantities or electrical signals.

Understanding the Conversion Process

Converters focus on signal type conversion and interface compatibility.

Transmitters emphasize signal accuracy, stability, and the convenience of subsequent processing.

In the Application of Flow Meters

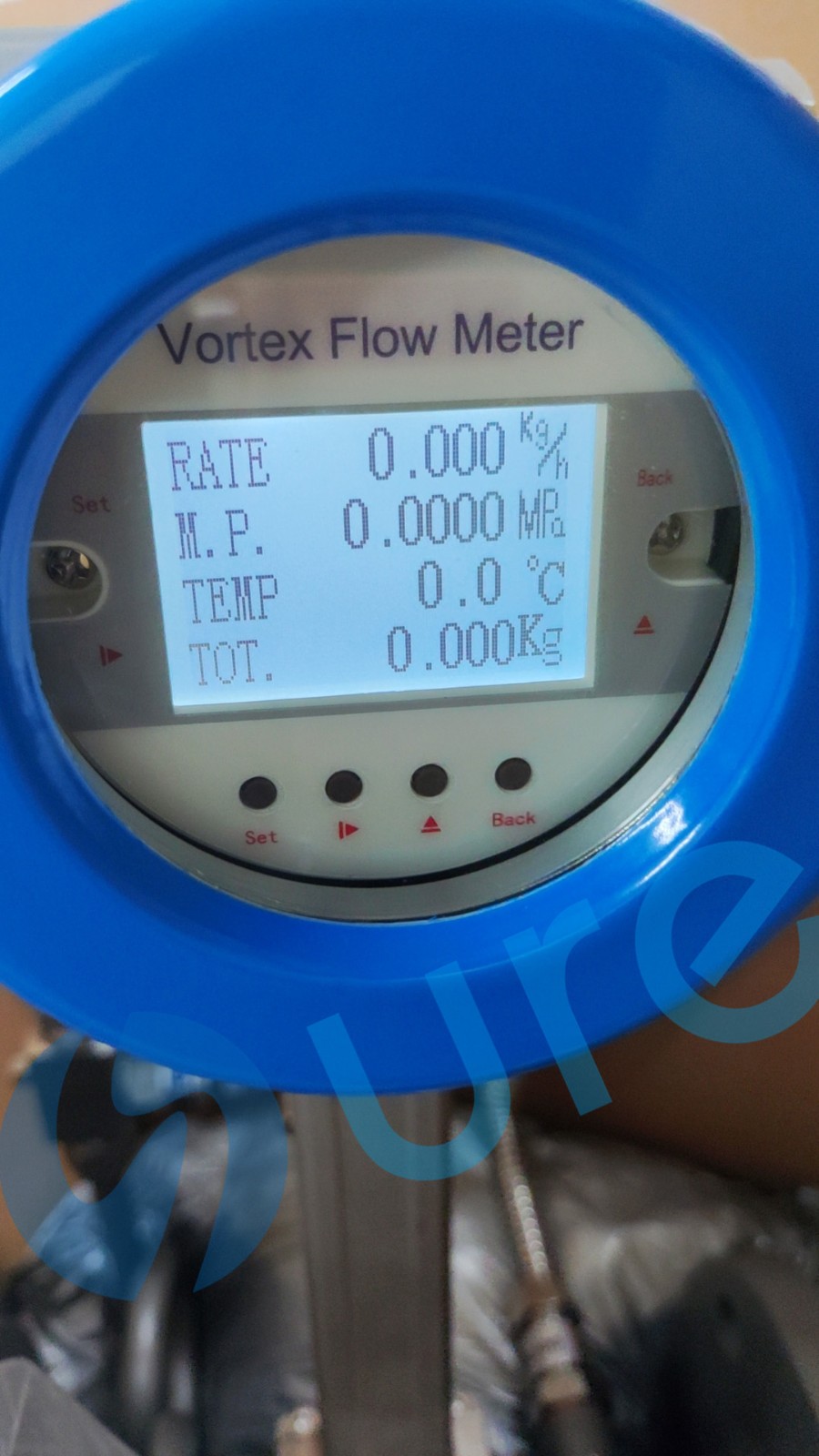

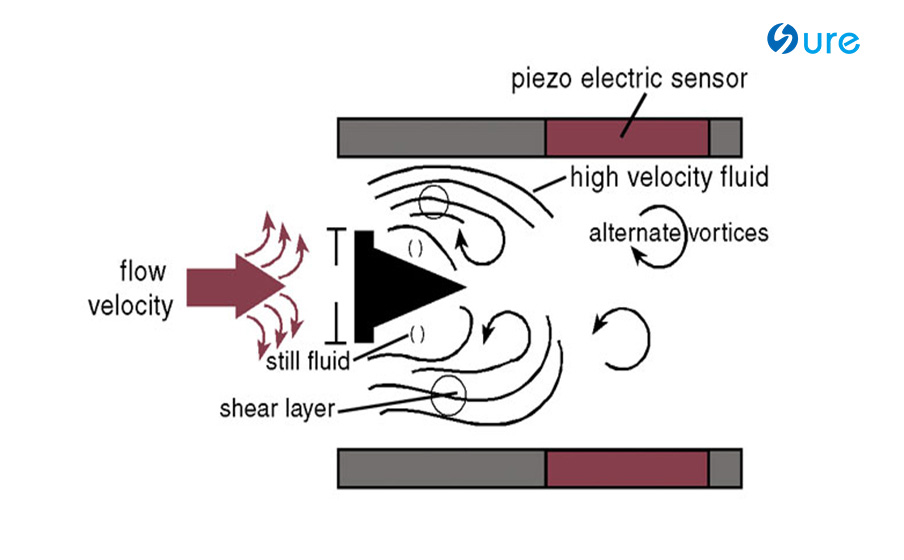

You might feel that "sensors" and "transmitters" pair well in the construction of flow meters because a transmitter can indeed encompass the function of converting sensor outputs into standard signals, aligning with the actual working principle of flow meters.

However, it's important to note that the use of terminology in industrial automation can vary by manufacturer, industry practices, or specific application scenarios.

Whether using "converters" or "transmitters" in the construction of flow meters, the core function is to convert the fluid flow signal detected by the sensor into a standard signal for output. These terms overlap in functionality, but "converters" often focus more on the signal conversion and processing, while "transmitters" may include additional features like signal amplification, linearization, and isolation.

In practice, many manufacturers and documents use the combination of "sensors" and "converters" to describe the construction of flow meters because "converters" more directly describe the process of converting sensor signals into standard signals. The term "converter" also has a high level of recognition and universality in the field of industrial automation.

Of course, some manufacturers or documents may use the combination of "sensors" and "transmitters" to describe the construction of flow meters. In this case, the "transmitter" may include the functions of the converter and some subsequent processing circuits, forming a more complete signal conversion and output unit.

In summary, both "converters" and "transmitters" are reasonable term choices when describing the construction of flow meters. The key is to understand their respective functions and roles, and select the appropriate terminology based on specific application scenarios and manufacturer standards. In practice, you can refer to the manufacturer's documentation, technical manuals, or industry standards to determine the correct usage of terms.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.