Contact Us Right Away

If you run into any issue or have any question.

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

LNG regasification and pressure reduction skids are essential natural gas supply systems designed for the needs of small and medium-sized enterprises, as well as large-scale public construction users. They are widely used for emergency gas supply, residential community gas supply, and industrial production gas supply.

The LNG regasification and pressure reduction process primarily consists of two parts: the regasification of LNG and the subsequent pressure reduction (metering and odorization) of the gasified natural gas to the required pressure for use.

LNG Regasification

The main equipment for LNG regasification is the ambient air vaporizer, which operates on the principle of utilizing the temperature difference between the environment and LNG to increase the temperature of LNG flowing through the vaporizer pipes, thus converting it into a gaseous state. Post-regasification, LNG is commonly referred to as NG (natural gas).

If ambient temperatures are too low, the gasified natural gas may require secondary heating, known as reheat. After reheat, the natural gas undergoes filtration, pressure reduction (metering and odorization), and is then ready for connection to the gas usage points. In this process, flow meters are essential for measuring the flow rate of the gasified natural gas.

Application Case

For a project aimed at meeting the production gas needs of a certain enterprise, a regasification and pressure reduction skid was set up within the factory area, which includes three metering pipelines, each designed for a flow rate of 100-500 Nm³/H, with two in use and one on standby, allowing up to two metering pipelines to be activated simultaneously. Each metering pipeline automatically activates based on set flow rates, and if the actual flow in a pipeline exceeds 90% of the designed flow, the system will automatically activate the next pipeline. During maintenance, operators can also manually control the metering pipelines according to on-site conditions. Each metering pipeline includes a flow meter, pressure transmitter, temperature transmitter, and flow totallizer.

Customer Requirements

Accurately measure gas consumption and ensure normal gas usage during calibration or maintenance.

Measure gas flow and convert it to standard conditions.

The instrument must perform stably, measuring pressure, temperature, and other parameters accurately.

Solution

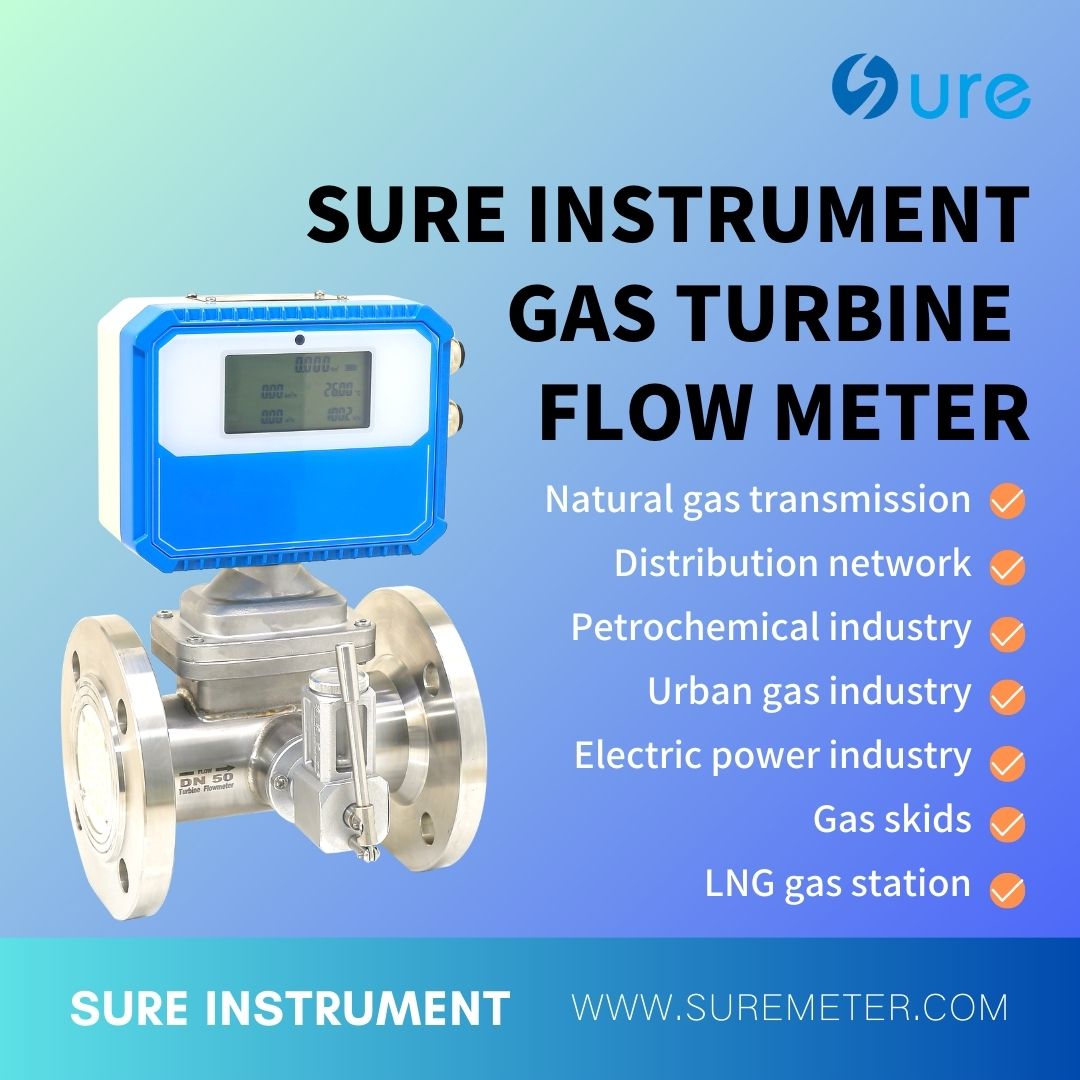

After on-site communication with technical personnel, it was determined that the flow measurement would use a temperature-compensated gas turbine flow meter with a metering accuracy of 1.0 grade. The turndown ratio is greater than 1:16, meeting the metering precision requirements for both minimum and maximum flow rates. The flow meter is equipped with a volume correction instrument that automatically converts actual flow to standard flow and performs automatic corrections for temperature, pressure, and compression coefficients. It can store data for up to one year or longer, enabling automatic management and monitoring of flow. With two operating gas pipelines and one bypass, uninterrupted gas supply is maintained during meter calibration or maintenance.

Customer Feedback

The customer reported that the flow meter selected for this project fits the pipeline design perfectly. Since its deployment, the meter has not only ensured the precision of flow data but also maintained long-term stable operation, reducing energy waste and cost losses due to errors and malfunctions. Additionally, its compact structure and rational design save installation space and simplify daily maintenance and upkeep. The instrument's user interface is straightforward and intuitive, significantly reducing the technical barriers and time costs associated with daily operations and maintenance for the enterprise.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.