Contact Us Right Away

If you run into any issue or have any question.

Ultrasonic Magnetic Vortex Flow Meter Manufacturer, Sure We Are, Sure To Be Better | ✉ overseas@suremeter.com

Liquid turbine flowmeters are precision instruments widely recognized for their accuracy and reliability in measuring the flow rate of liquids. They operate on the principle of measuring the rotational speed of a turbine rotor, which is directly driven by the fluid flow. This technology is particularly suited for applications requiring high precision and repeatability, such as in the chemical, petroleum, water treatment, and food processing industries. The flowmeter's design, featuring a multi-blade rotor that spins with the fluid's momentum, allows for a wide flow range and excellent turndown ratios. However, as with any sophisticated mechanical device, these flowmeters can occasionally encounter issues that require troubleshooting and maintenance, which is where Sure Instrument's after-sales support comes into play. In our case studies of common after-sales issues, we will explore the challenges that may arise with liquid turbine flowmeters and the solutions we implement to ensure their optimal performance and longevity.

Case Introduction:

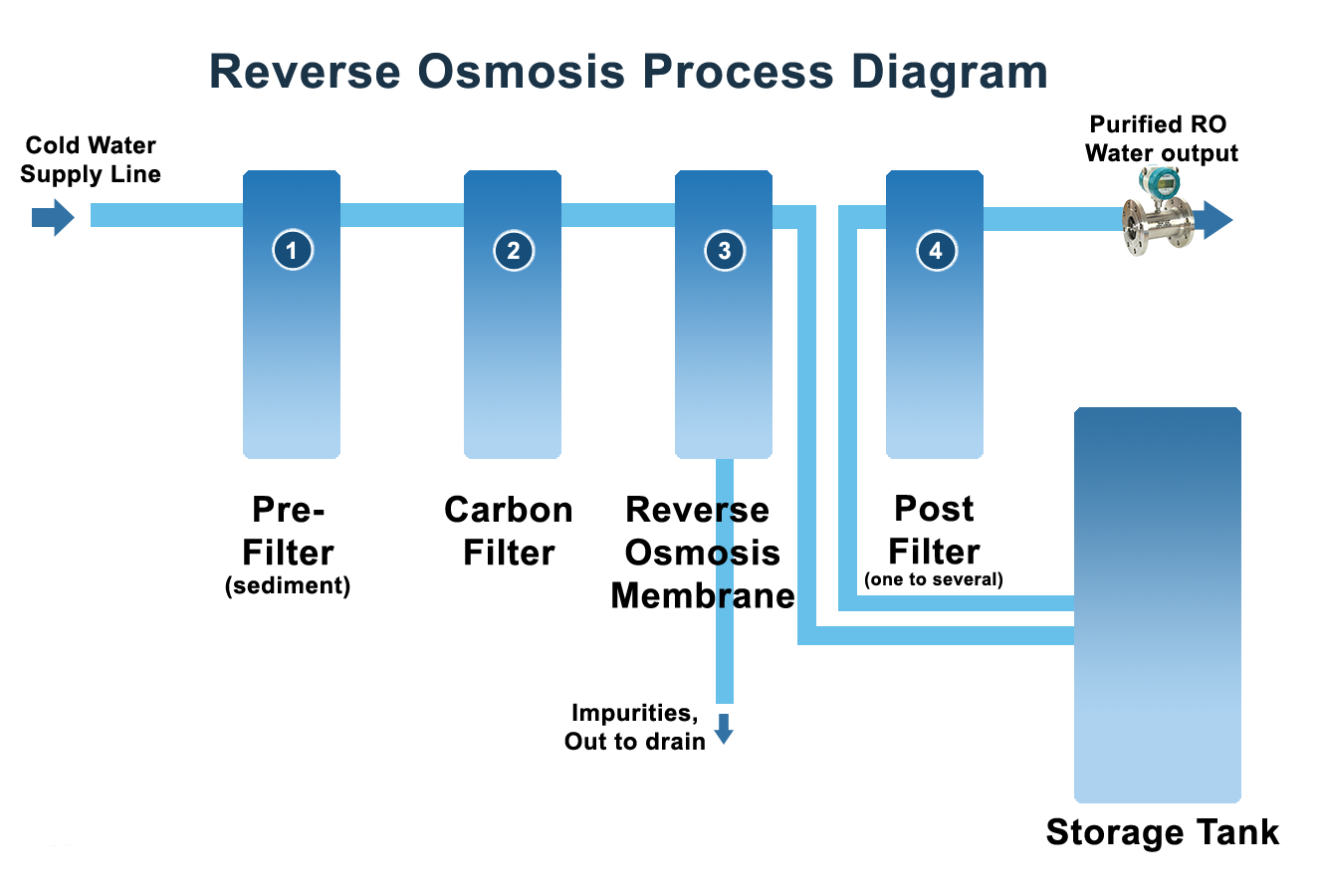

A municipal water treatment plant has incorporated a DN25 Sure Instrument liquid turbine flowmeter into its purification process for monitoring and controlling the flow of pure water. This flowmeter plays a crucial role in the plant's reverse osmosis (RO) system, ensuring that water quality meets high standards. Since its installation, the flowmeter has been operating steadily for two months, providing the plant with accurate flow data and safeguarding the continuity and efficiency of the water treatment process.

Recently, plant operators noticed during routine monitoring that the instantaneous flow of pure water displayed by the liquid turbine flowmeter suddenly dropped to 0, even though other parts of the system indicated normal operation. This abnormal situation immediately caught the attention of the plant's technical team, as it directly affects the production efficiency and water quality of the water treatment plant.

Troubleshooting Steps:

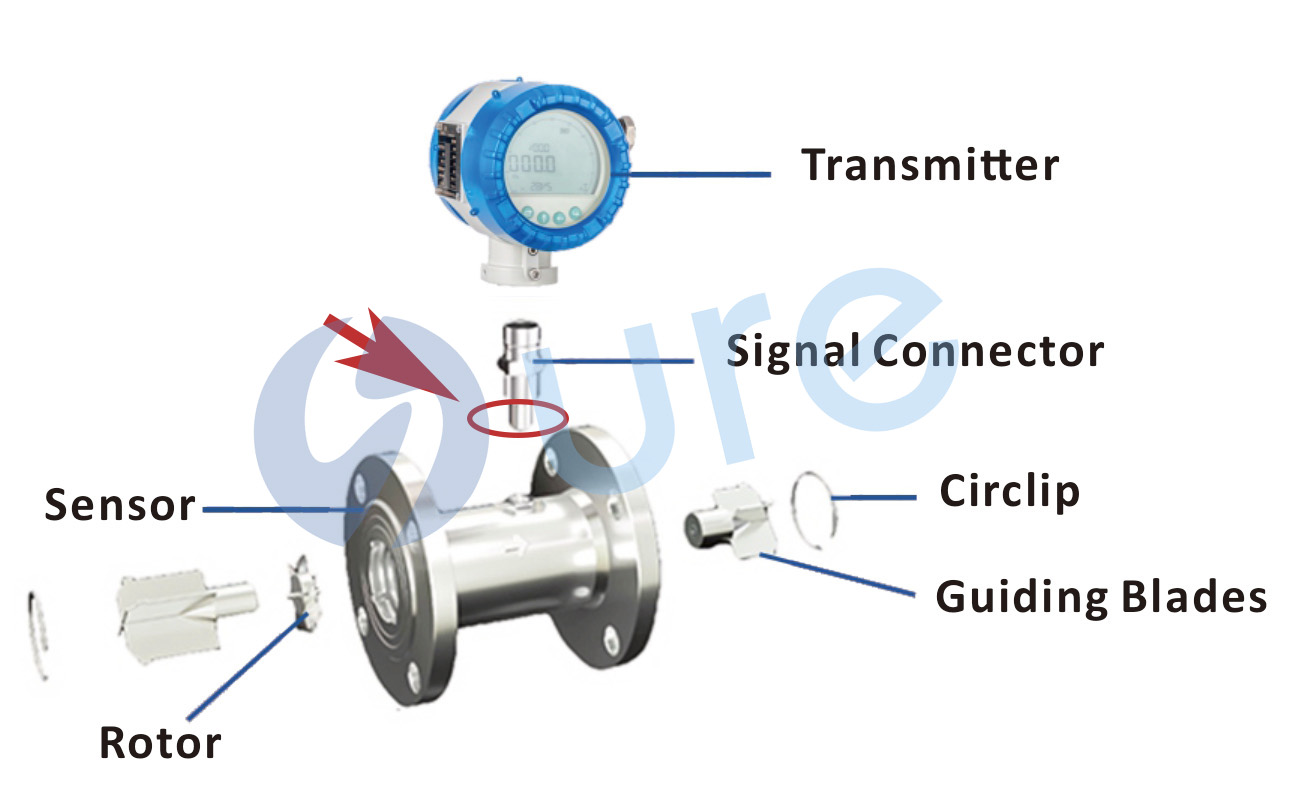

1.Swipping the Signal Sensor Part:

Ensure that the operator correctly swipe the signal sensor part of the flowmeter.

2. Checking the Meter Movement:

If the flowmeter displays an instantaneous flow rate, proceed to dismantle the instrument to inspect the condition of the movement or mechanism inside.

If there is no instantaneous flow displayed, examine the meter's parameters, signal plug, and measure the resistance of the signal coil.

3. Examining Meter Parameters:

Check the following parameters within the flowmeter settings: flow cut-off, frequency upper limit, coefficient correction, and coefficient value.

4. Signal Plug Connection:

Verify that the signal plug is securely inserted and not loosely fitted. A poor connection can lead to incorrect readings or no reading at all.

5. Measuring Signal Coil Resistance:

The resistance of the signal coil should be within the normal range. Typically, the coil resistance is around 1.4KΩ. Use a multimeter to measure the resistance and ensure it falls within the manufacturer's specified range.

6. Circuit Board Signal Reception:

If the circuit board is not receiving signals, inspect the board for any visible damage or loose connections. Ensure that there are no obstructions or defects that could prevent the board from functioning properly.

Please follow these steps carefully to diagnose and resolve the issue with your flowmeter. If the problem persists after following this guide, it is recommended to contact the manufacturer or a professional technician for further assistance.

Solution:

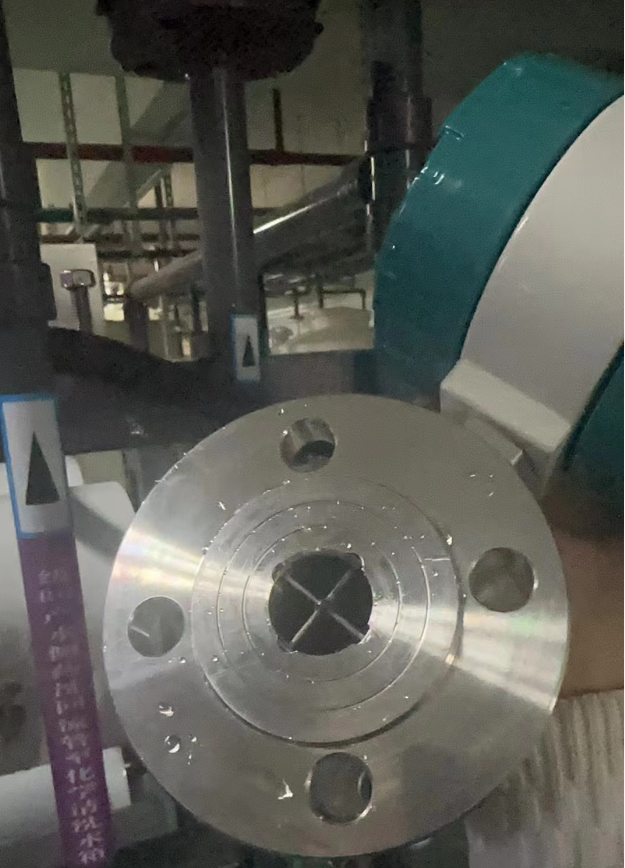

According to the troubleshooting steps, we swipped the signal sensor part and confirmed the presence of instantaneous flow. Upon disassembling the flowmeter, we observed that the rotor was not rotating when manually probed. This suggests a mechanical obstruction or failure within the rotor part. Further inspection revealed that the rotor was jammed due to a foreign object lodged within the rotor.

To resolve this issue, it is recommended to:

Clean and Inspect: Carefully remove the foreign object and inspect the rotor for any damage or signs of wear.

Reassemble and Test: After clearing the obstruction, reassemble the flowmeter and conduct a test to ensure the rotor spins freely and the flow signal is restored.

Routine Maintenance: Implement regular maintenance checks to prevent future occurrences of foreign objects entering the measurement section and causing similar issues.

By following these steps, Sure Instrument finally ensure the proper functioning of the liquid turbine flowmeter, and maintain the integrity of the flow measurement process.

With Strong emphasis on talent acquisition and internal promotion. Sure Instrument has a high profile team of engineers that are ready to offer fluid measurement solutions and trouble shooting service to our valued clients! Please feel free to reach our to us 24/7!

Our products usually come with a one-year warranty against any quality issues, during which we will provide free replacements if necessary. We are committed to offering continuous online post-sales support and, when required, dispatching technical personnel to the site for hands-on assistance.

Copyright © 2025 Tianjin Sure Instrument Co., Ltd. | All Rights Reserved 津ICP备08002549号-2

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.